On this Sunday, November 24, 2024, we are hard at work to begin work on the VroumVroum!

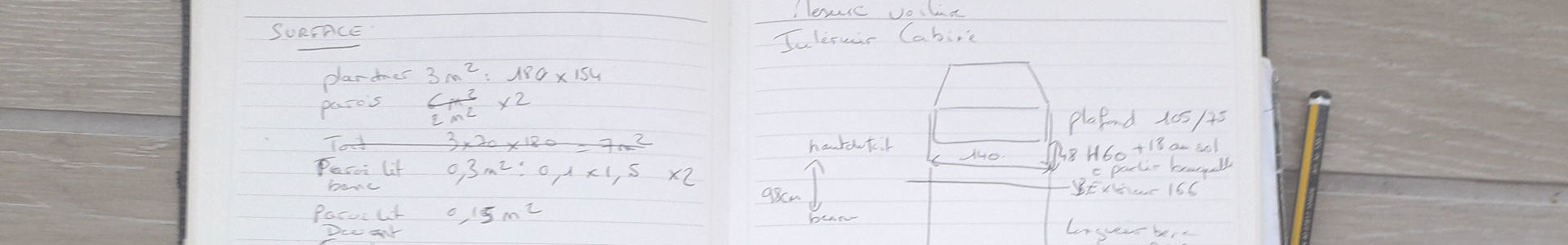

But what will it really look like?

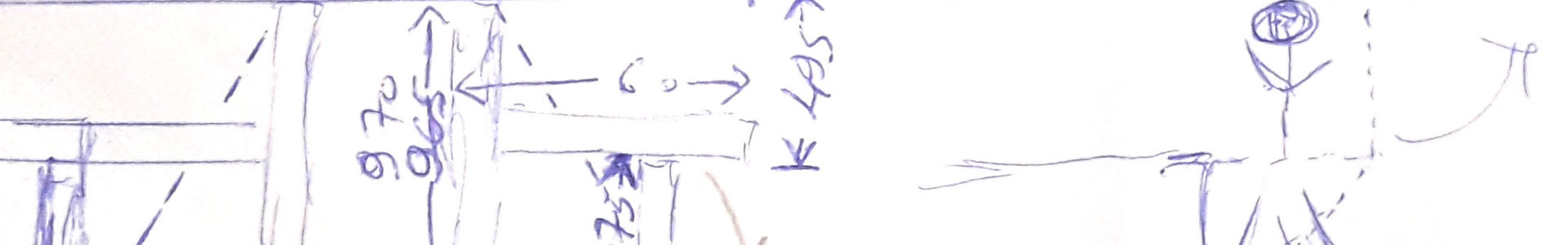

Our goal is to build a truck camper that is as discreet as possible, that is to say less than two meters from the ground, that does not exceed the width of the cabin, and that is as light as possible while remaining solid and reliable.

What a challenge!

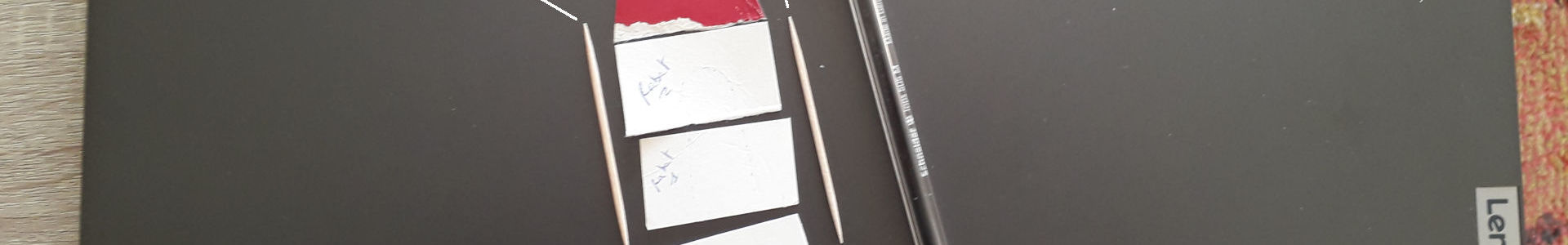

So in the video below, we think about it, fumble around, and then we come to the conclusion that we must start by sawing the essential wood for the frame, which we will then place in situation to get a better idea.